GRABO® Quality Engineering

GRABO® makes heavy lifting easier. We drive innovation in the vacuum suction cup industry and continue to create products to make job site lifting simple.

The Professional Way to Move Almost Anything

We take vacuum suction lifting to the next level, using electric motors, digital vacuum sensors, and remote options to make moving material the easiest part of the job.

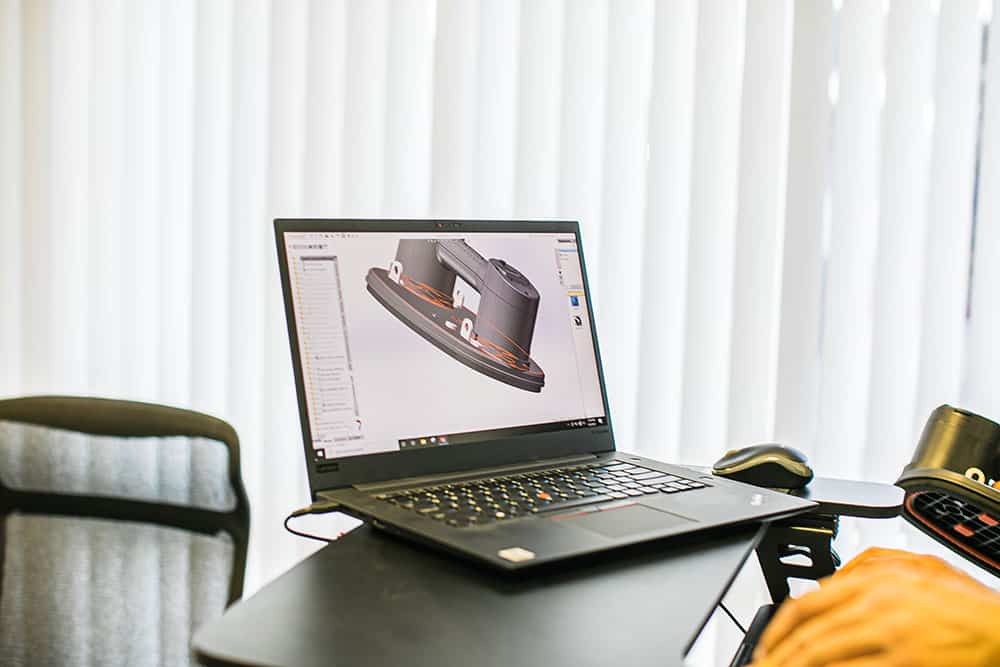

Our R&D engineers span the globe, developing groundbreaking technologies and innovative tools to make your life easier.

We Built Our Reputation By Offering:

- High-End Technology: We use marine-grade sealing and fabrication components and drone-quality electronics to maintain the highest build standards.

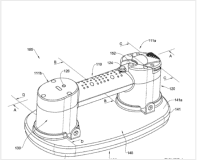

- Patented Vacuum Lifting Technology: Anti-slip, effortless grip, and powerful lifting. Our unique patented technology is unmatched for portable lifting with ease.

- Convenient Long Reach Extensions: Created with advanced ergonomics for comfort, our extensions speed up hard-to-reach projects.

- Intelligent Tools: Keeping you informed every step of the way with smart pressure sensors, vacuum adjustment settings, and clear digital displays.

- Remote Operation: Control your GRABO® from a distance with our remote add-on options.

- High-Flow Vacuum Pumping: Working with dry, porous materials? Our high-flow vacuum options help to move these tricky materials.

Maintaining a Seal with Porous Materials

Porous materials are a challenge. The small holes in some wood, concrete, and ceramic materials let air escape from most vacuum technologies.

Suction often fails on uneven surfaces and porous materials. GRABO® technology uses patented air-balancing technology to bring air into the vacuum at a faster rate than it can escape.

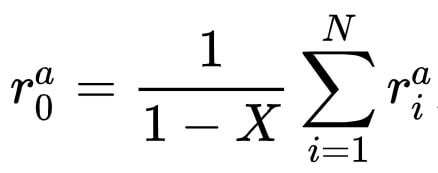

Using the principles of Murray’s Law, we design GRABO® tools for maximum performance.

Our vacuum pump rate is so high, GRABO® tools can handle the most complex surfaces without losing suction.

We determine the flow rate for porous materials using a formula based on Murray’s Law.

Our extensive research into the properties of porous material helps us create the vital technology required for the GRABO® to create a safe and powerful vacuum seal.

You don’t need to understand how GRABO® works to enjoy a faster work rate and less body strain.

What is a Vacuum Gripper (GRABO®)?

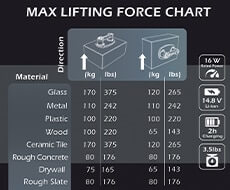

GRABO® takes lifting with suction to the next level. Manual suction cups provide some help with lifting, but using electric vacuum technology, GRABO® lifters can move up to 375 lbs quickly and more safely.

Our portable electric vacuum tool uses a rigid base and a string seal element. The flexible seal contacts a surface and conforms to the material.

Creating a chamber for high-suction vacuum pressure, our powerful technology uses an advanced air pump and specialized sealing technology to continuously move air while retaining a strong grip.

GRABO® technology is an investment in safety, speed, and efficiency on-the-job.

Become a GRABO Insider

Want the latest news on new GRABO electric lifter technology? Get access to priority updates and other exciting bonuses now.